"Are there any safety mechanisms to make sure it doesn't accidentally blend my face if I get too close?" I asked the engineer, as I watched two humanoid robotic arms prepare a delicious crab bisque from scratch. The engineer took a moment to respond, not entirely sure of the correct answer. "Well... not really..."

A couple of weeks ago, I was invited along to a warehouse in north London to see what is being billed as "the world's first automated kitchen." The system, made by Moley Robotics in the UK, can only make crab bisque right now—and it requires that all of the ingredients and utensils are pre-positioned perfectly. The goal, though, is to have a consumer-ready version within two years, priced at around £10,000 ($14,600). The company envisions an "iTunes style library of recipes" that you can download and have your robot chef prepare.

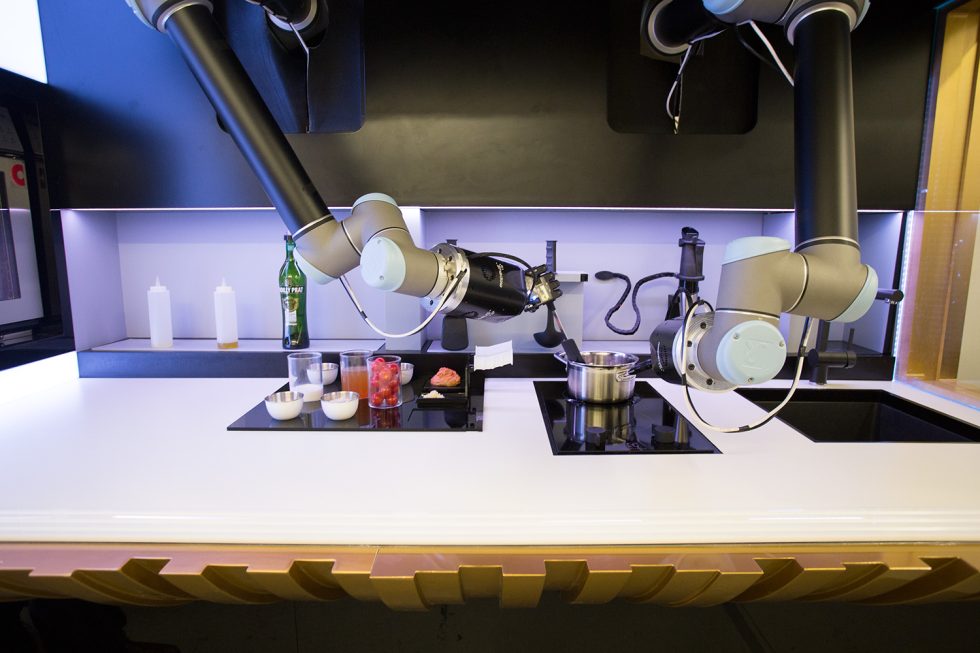

In its current form, the Moley Robotic Kitchen is essentially two very expensive robotic arms, with two even dearer fully articulated biomimetic humanoid hands made by the Shadow Robot Company on the ends. In front of the robot is a kitchen—a sink, a stovetop, an oven, and a range of utensils, including the aforementioned blender. The ingredients are placed in bowls and cups on the worktop. Once everything is set up, an engineer simply presses "start" on the controlling PC, the robot arms whirl around for 30 minutes, and voilà: crab bisque.

OK, crab bisque, but has this thing evolved to make a passable gravy? #tbt https://t.co/q6rt9bCT7Z pic.twitter.com/AwUQnXMaVs

— Ars Technica (@arstechnica) November 23, 2017

To make crab bisque from scratch, you must first...

But how did Moley make the Robotic Kitchen in the first place? First of all, let me be quite clear: this robot is actually quite dumb. The Robotic Kitchen is replicating the exact movements of Tim Anderson, the 2011 winner of the television show MasterChef. Moley set up an exact copy of the kitchen, placed some motion-capture cameras around the room, and then recorded Anderson while he cooked a crab bisque. The engineers told me that they recorded Anderson making the bisque five times, at a sample rate of 100Hz; they then took the cleanest moves from each run and put them into a database.

To make the bisque, the database is executed through a PC running Robotic Operating System (ROS), a robotics platform that usually sits on top of Linux (in this case, Ubuntu). It's really that simple.

That's what I meant earlier by the system being dumb: there's almost no logic at all during the execution. All of the intelligent thought was carried out previously by the human chef. The Robotic Kitchen is essentially a culinary photocopier, producing batches of crab bisque entirely from memory. If anything is out of position by even a few millimeters, it's game over. If the saucepan's handle is slightly out of position, the hand will just grab at thin air. If you accidentally set the ingredients up in the wrong positions, the robot is none the wiser; it doesn't care if it accidentally grabs the stock instead of the cream.

-

The Moley Robotics lab. You can see the motion-capture system, and the identical kitchen that was used by the chef, on the left-hand side.Sebastian Anthony

-

A Shadow Robot hand stirring some ingredients.Sebastian Anthony

-

Robotics Operating System (ROS).Sebastian Anthony

-

The Moley Robotic Kitchen, early in the crab bisque cooking process.Sebastian Anthony

-

Side view of the Moley Robotic Kitchen.Sebastian Anthony

-

The finished crab bisque.Sebastian Anthony

-

The robot admires yet another perfect crab bisque.Sebastian Anthony

Don't get me wrong, though. Watching the Moley Robotic Kitchen create a bowl of soup from raw ingredients was seriously impressive. It isn't often that I'm humbled by technology, but on numerous occasions with the Robotic Kitchen I caught myself staring, mouth agape. When I noticed the robot was replicating even the tiniest of moves—the gentle scrape of a spatula against the side of a saucepan, the tiny "dance" of the chef's hands as it watches the broth simmer, the stabilizing hand on top of the blender—I found myself pondering what magic must be at work inside those robotic hands.

Culinary Judgment Day

For the time being, then, you can allay any concerns about a culinary Judgment Day. The Moley Robotic Kitchen, which is being shown off at the Hanover Messe industrial robotics show this week, is a tantalizing taste of what's to come, though. Within two years, if Moley can find a way of cheaply mass producing the robot arms and hands, the company hopes to be able to sell a complete Robotic Kitchen module for £10,000. There are also plans to add some intelligence to the system, though the timeline for such additions is uncertain. The addition of computer vision, for example—so the robot can actually see what it's doing, rather than just going through the recorded motions—would allow for safer, more reliable operation.

Ultimately, Moley envisions a future where, if you have a robotic kitchen, you can simply download recipes from a digital store. Because of the way the system works, you could theoretically buy "Gordon Ramsay's soufflé" and have the robot prepare the dish in exactly the same way as Ramsay himself. Maybe recipe books of the future will come with a USB stick pre-loaded with "the top 20 crumpet recipes of all time"—and of course, cooking websites and blogs would offer complete robotic playback files rather than just listing recipes.

When I quizzed some of the people in the room about the over-automation of everyday life, they were ambivalent: yes, there will probably be push back from consumers and decision makers—but the benefit of having an automated Michelin Star chef in your kitchen far outweighs most concerns. As one of the engineers said to me, "Imagine being able to wake up to a full English breakfast every morning." There is also a good case to be made for the educational use of a Robotic Kitchen: what better way to learn how to make a complex dish than to watch a pair of humanoid hands make it a few times?

The crab bisque, in case you were wondering, was absolutely delicious. Between slurps, I asked the chef—the human winner of MasterChef that is—the most important question: "Does the robot make better bisque than you?"

"Yep. It's more reliable. It makes a good bisque every time. I'm only human—there's a lot more variation when I make it."

reader comments

103